Shear connector stud

The shear connector increase the strength of your structure. They act as reinforcing anchors,... Read More

Panchvaktram Engineering Private Limited (PEPL) provides quality engineering products like shear studs and Headed stud shear connector, project management and construction solutions to core industries. We are an ISO Certified company that bring you Brimming with energy, innovation, quality and excellence, Panchvaktram Engineering offers new quality products from internationally reliable and prominent manufacturers as a best fit solution to its valuable clients.

Read MoreOur Vision is to establish Panchvaktram Engineering Private Limited as the most trusted...

rovide the highest level of quality products and services at fair and prevailing market prices....

Our Core Values define who we are, how we work, what we believe in and what we stand for...

As the name PANCHVAKTRAM implies creation of the world from nothing, the company aims to consistency grow to a respectable global preferred engineering partner, utilising its people and technical expertise We are leading manufacturer and supplier of shear connectors stud in India. Our shear deliver code specified shear strength value as used in composite construction, securing concrete to steel structural components. We provide end to end solution including studs, studs welding equipment, stud installation and technical support also we have executed numerous prestigious projects over the last 12 years We always maintain considerable amount of stock with us to cater our customer’s urgent requirements.

Panchvaktram Engineering takes pride in offering best fit solution catering to the requirement of its

clients

Our motto at Panchvaktram is UNLESS WE HAVE 100% CUSTOMER SATISFACTION, WE MUST IMPROVE.

This motto drives our team on all frontiers to excel in the work we do.

The shear connector increase the strength of your structure. They act as reinforcing anchors,... Read More

Stud welding is widely used in construction building (industrial & commercial), Bridge... Read More

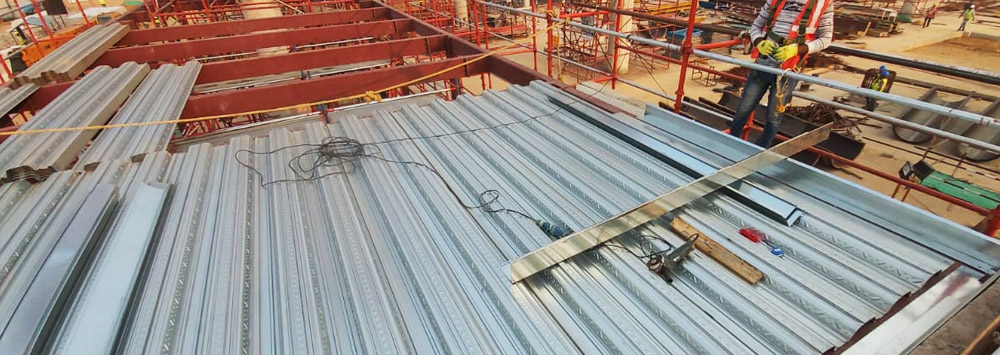

Deck Sheets can be used as a working platform during construction. Speedy construction... Read More

Our Stud-welding is capable Welding Equipment with Gun Series (SDA 3150) System can... Read More